Renown’s Quality Policy is to determine, agree & conform to customer needs and expectations whilst fulfilling the requirements of ISO 9001:2015. The Company recognises that to be competitive & maintain good economic performance, we must employ management systems that continually improve the quality of our products & increase the satisfaction of our customers, employees, shareholders, suppliers and society at large.

Downloads

The Quality Management System provides:

- Confidence of our Customers that their requirements for quality and safety are being achieved in the delivered product.

- Confidence of our management and staff that the requirements for quality are being fulfilled and maintained, and that quality improvements take place.

- A framework for establishing and reviewing quality objective.

We are conscious that the motivation of our employees is dependent on their training and understanding of the tasks they are expected to perform. It is part of our ongoing training programme that this policy is communicated and understood at appropriate levels in the Company.

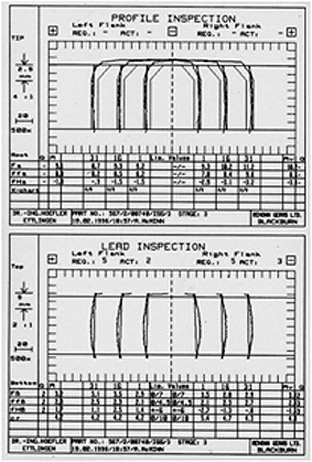

CNC Gear Inspection:

State of the art technology in gear metrology, A4 plotted graphs of profile, lead, adjacent pitch, cumulative pitch and total runout ensure that the standard criteria are met. At the heart of their temperature controlled gear inspection room, are two dedicated CNC Gear Measuring Machines and a DEA (Hexagon Metrology) CMM.

M & M Sigma V3:

Ultimate inspection performance from today’s most advanced probe, drive and control systems. Column-type gear measurement machine (GMM) with rotary table, granite base, cast iron slides and motorised tailstock

- 3D Probe Technology

- Proven four-axis generative motion

- M & M software with windows based interface

- Both external and internal measuring

- Maximum diameter – 360mm

- Measuring range from 0.1 to 18 mod

- Temperature monitoring system

- Probe changing system

Hofler ZME 402:

The ZME has three CNC-controlled axes that can precisely measure any cylindrical gear. The robust construction and the small moved mass make highest measuring and positioning speed possible.

- 3 CNC controlled axis

- Fully automatic measurement of Involute, Lead, Pitch and Runout

- Maximum diameter – 420mm

- 3D measuring probe

- Measurement of all externally toothed cylindrical gears

Diagrams:

Both machines analyse the standard criteria whether DIN, AGMA or ISO.

The following features are measured precisely in one revolution of the gear:

- Involute Profile

- Lead

- Adjacent Pitch

- Cumulative Pitch

- Pitch Line Run Out

Note: All documentation is traceable and retained between 5 and 15 years dependant on customer requirements.